Table of Contents

Did you know that you should always wear rubber gloves? Electrical rubber gloves provide protection against electric shock. They also protect your hands from burns and other injuries. In this blog post, we will discuss the different classes of rubber gloves and when you should wear them, including the PPE requirements. We also provide answers to some frequently asked questions about rubber gloves utilizing.

Rubber gloves, whether crafted from natural or synthetic rubber, serve as your trusty shield against a wide range of hazards. These gloves are purpose-built to safeguard your hands from potential dangers such as electrical shocks, harmful chemicals, and other hazardous substances. With a variety of sizes, thicknesses, and colors available, rubber gloves can cater to your specific needs and preferences. Moreover, they boast varying levels of resistance to electricity, heat, and chemicals, ensuring optimal protection in diverse environments. Embrace the reliable defense provided by rubber gloves and keep your hands safe from harm.

OSHA Ratings for Rubber Insulating Gloves

In the realm of electrical work, having the right protective gear is essential. This includes using rubber gloves that are designed to provide insulation against electrical hazards.

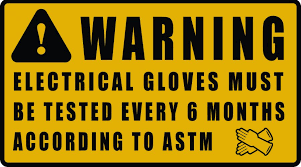

OSHA (Occupational Safety and Health Administration) has established stringent guidelines to ensure the safety of workers using rubber insulating gloves. These guidelines are based on the ASTM D120 Standard Specifications for Rubber Insulating Gloves. OSHA’s ratings for rubber insulating gloves provide clear indications of the maximum voltage they can effectively protect against.

Class 00

Class 00 gloves are rated for a maximum voltage of 500V (AC) and 750V (DC). These gloves are suitable for low-voltage applications that require limited protection.

Class 0

Class 0 gloves offer increased protection and are rated for a maximum voltage of 1000V (AC) and 1500V (DC). They are designed to safeguard against electrical hazards in environments with moderate voltage exposure.

Class 1

For higher voltage environments, Class 1 gloves are recommended. Class 1 rubber gloves have a maximum AC use voltage of 7,500 volts and a maximum DC use voltage of 11,250 volts. These gloves are designed to provide protection against electrical hazards and are suitable for use in environments where the voltage exposure does not exceed 7,500 volts (AC) or 11,250 volts (DC). They offer reliable insulation and are commonly used by electricians and workers in industries with moderate voltage requirements.

Class 2

When working with high-voltage systems, Class 2 gloves are essential. They have a maximum AC use voltage of 17,000 volts and a maximum DC use voltage of 25,500 volts. These gloves are specifically designed for working with electrical systems and equipment where the voltage exposure can reach up to 17,000 volts (AC) or 25,500 volts (DC). They offer enhanced insulation properties and are commonly used in applications involving high voltage power distribution, electrical maintenance, and industrial settings.

Class 3

For even higher voltage applications, such as utility work, Class 3 gloves are suitable. They have a maximum rating of 26,500V (AC) and 39,750V (DC), providing increased protection against electrical shocks.

Class 4

Lastly, Class 4 gloves offer the highest level of protection, with a maximum rating of 36,000V (AC) and 54,000V (DC). These gloves are designed for extremely high-voltage environments, such as high-power electrical systems and utility substations.

It is crucial to choose the appropriate class of gloves based on the specific electrical work being performed and the voltage exposure involved. Using gloves with the correct voltage rating ensures that workers are adequately protected against electrical shocks and potential hazards. Regular inspection and testing of gloves are also necessary to ensure their continued effectiveness and reliability. By following proper safety protocols and utilizing the right class of rubber gloves, workers can mitigate the risks associated with electrical work and promote a safer working environment.

Why Should You Wear Rubber Gloves When Working with Electricity?

Because rubber is an extremely poor conductor of electricity, it prevents the electric current from passing through it. Therefore, rubber gloves are specifically designed for electrical work, providing crucial protection against electrical shocks. These gloves act as a barrier, shielding the electrician from potential harm while repairing an electric switch or device.

In addition to their electrical insulation properties, rubber gloves offer additional benefits for electricians. They provide a protective layer that safeguards the hands from cuts or burns that may occur when working with electrical wiring. This is particularly important as electrical work often involves handling sharp tools or working in confined spaces where accidental injuries can happen. The gloves also serve as a barrier against dirt and oil, helping to maintain cleanliness and hygiene during electrical tasks.

By using rubber gloves designed for electrical work, electricians can confidently carry out their duties knowing they are protected from electrical hazards, potential injuries, and contamination. These gloves play a vital role in ensuring the safety and well-being of electricians, allowing them to focus on their work without compromising their personal protection.

Types of Electrical Safety Gloves

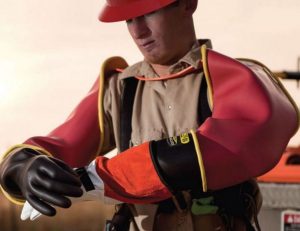

Electrical safety gloves are essential for protecting workers from electrical hazards. These gloves are classified based on their OSHA ratings and material resistance. OSHA ratings determine the maximum voltage the gloves can withstand, while material resistance differentiates between Type I and Type II gloves.

Type I gloves are made from natural rubber and lack ozone resistance, while Type II gloves are constructed from synthetic rubber and offer ozone resistance. However, only Class 00 and Class 0 gloves are available in both Type I and Type II, while all other classes are made with Type I rubber.

Electrical safety gloves come in various designs, which include voltage ratings, cuff styles, and colors. Voltage ratings categorize the gloves based on the maximum voltage they can withstand, with Class 00 being the lowest and Class 4 being the highest. Cuff styles vary, with straight cuff, bell cuff, and contour cuff options available. However, Classes 00, 0, and 1 are typically only available in straight cuff, while Classes 2, 3, and 4 offer all three cuff styles. Color options include red and black for lower classes (00 and 0), while dual-color gloves are common for higher classes. The color choice does not affect the gloves’ integrity but is a matter of personal preference.

When discussing high voltage versus low voltage gloves, low voltage generally refers to Class 00 and Class 0 gloves, while high voltage encompasses Classes 1 through 4. Class 00 and Class 0 gloves are available in both Type I and Type II rubber, whereas all other classes are exclusively made with Type I natural rubber. The thickness of the rubber in these gloves is achieved through a dipping process, with low voltage gloves being thinner and high voltage gloves having increased thickness to withstand the specific voltage requirements of each class.

Wearing Rubber Gloves In Terms Of PPE

Personal protective equipment (PPE) plays a crucial role in protecting workers from potential hazards, and one essential PPE item that every electrical worker should have is a reliable pair of rubber gloves.

Rubber gloves serve as an important form of insulation, preventing electric current from passing through and coming into contact with the skin. They create a protective barrier that significantly reduces the chances of electrical shocks, ensuring the safety and well-being of electrical workers.

These gloves are designed to meet specific safety standards, including the Occupational Safety and Health Administration (OSHA) ratings and ASTM D120 specifications. These standards ensure that the gloves can withstand the maximum voltage levels associated with different classes. For example, Class 1 rubber gloves are suitable for voltages up to 7,500 volts (AC) and 11,250 volts (DC), while Class 2 gloves provide protection against even higher voltages.

In addition to insulation, rubber gloves also offer excellent grip and dexterity. This allows electrical workers to handle tools, wires, and equipment with precision and confidence, enhancing their overall efficiency and productivity on the job.

However, it’s important to note that wearing rubber gloves alone is not enough to guarantee safety. Proper training, adherence to safety protocols, and regular inspection of gloves are equally crucial. Electrical workers should also be aware of the specific voltage levels they are working with and ensure they are using gloves that are appropriate for those levels.

In conclusion, rubber gloves are an essential form of PPE for electrical workers. They provide insulation, grip, and dexterity, helping to prevent electrical shocks and ensure the safety of those working with electricity. By investing in high-quality rubber gloves and following proper safety practices, electrical workers can carry out their tasks with confidence and peace of mind, knowing that they are protected by reliable PPE.

FAQs

- Why is it important to disinfect rubber gloves?

Disinfecting rubber gloves is essential for maintaining hygiene and preventing the spread of bacteria, viruses, and other contaminants. Regular disinfection helps ensure that the gloves remain clean and safe for reuse.

- How often should I disinfect my rubber gloves?

It is a good idea to disinfect your rubber gloves after each use. This will help to ensure that they are free of germs and bacteria.

- Can I wash my rubber gloves in the washing machine?

A: No, you should not wash your rubber gloves in the washing machine. Washing them by hand with soap and water is the best way to clean them. Thanks for reading! We hope this blog post has been helpful in understanding when and why to wear rubber

- Can you get shocked with rubber gloves?

Touching a wet rubber glove may shock you because the water conducts electricity. Rubber gloves won’t prevent electricity from passing if they aren’t made of 100 percent (pure) rubber. Rubber manufactured with cheaper conductive materials will not protect you against electricity.

- Do I have to send my gloves for voltage testing if I don’t use them very often and can’t see any damage?

Yes, retesting is required to verify the material’s integrity and to ensure that electrical safety is maintained for the user.

- Do latex gloves protect against static electricity?

Gloves constructed from natural rubber latex are statically insulative and cling to a charge and then release it in an uncontrolled way, resulting in damage. The surface resistance of nitrile gloves, on the other hand, is usually found on the verge of insulating and static dissipative.

Thanks For Reading!

We hope that this blog post has been helpful in teaching you about the importance of wearing rubber gloves when working with electricity. If you have any questions about best electrician gloves, please feel free to contact us. Thanks for reading!